Finding Data from Unexpected Sources

Recently MSIAC received a question about wool felt. At first this seems to be an inquiry best suited to our Scandinavian colleagues, whose knowledge of wool is probably much greater than those of us from southern climates. The inquiry, however, was targeted specifically at the shock and high-rate mechanical properties of woolen felt used extensively in munition fuze assemblies.

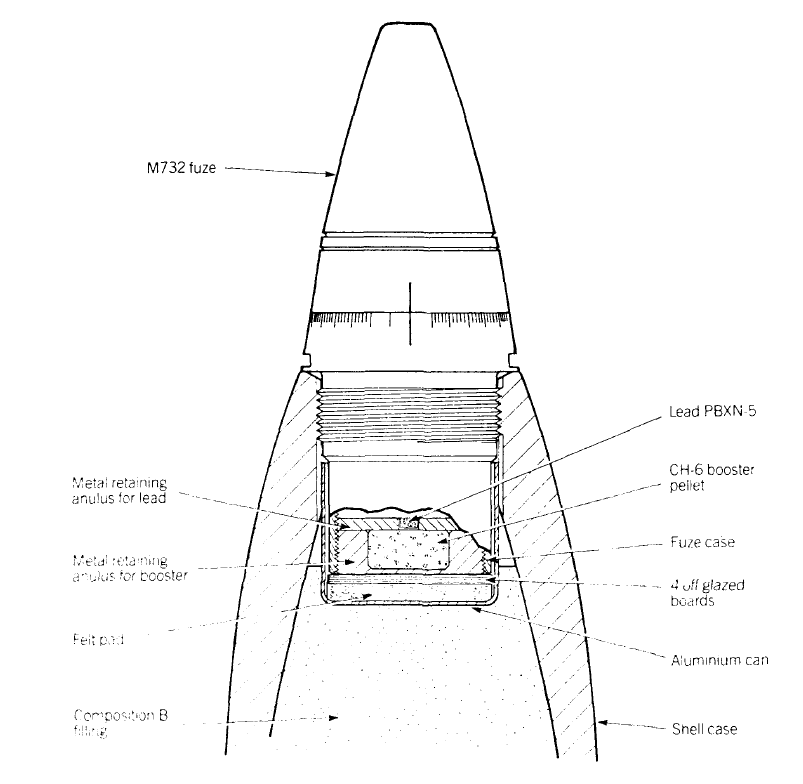

Upon receiving the question I did a quick review of MSIAC’s database of more than 130,000 insensitive munitions and munitions safety related documents, and found plenty of items that mentioned felt, and only a few with any material properties. Many of these referred to felt simply as a component in a system, like a “felt pad” or “felt disk”, and did not provide any properties beyond dimensions and sometimes density. We had a fairly large number of documents that discussed tensile and impact properties of non-woven, aramid-based felts, but these were exclusively armor applications, and neither the materials nor the mechanical behaviors were relevant to the inquiry.

What fascinated me immediately was the simple fact that so many munition devices include wool felt as a component. A review of the general properties of wool revealed some interesting characteristics. First, wool fibers are very environmentally stable, absorb little moisture, and resist dimensional or flexibility changes with temperature excursions. Second, felted (randomly fluffed and packed fibrous meshes) wool pads have very predictable mechanical properties, have predictably hysteretic compression and release behaviors, resist relaxation when compressed for long periods, and rebound well when loads are released. Further, it has proven very difficult to create man-made fibers and felts that can replicate many of these properties. All of this helps to explain why wool felt has been such a seemingly invisible but important part of so many munition systems.

That being said, the goal of the inquiry was to understand the mechanical properties better, and perhaps find data or a behavior model that could be used for high-rate loading and shock simulations.

It appears that the most relevant material science evaluation of woolen felts is in the study of piano hammers. In this application, a thin layer of wool felt is adhered to a smooth wooden mallet, which is then struck on a tightly strung metal wire. As the felt’s mechanical behavior (compression densification, rebound, mechanical damping, etc.) plays a critical role in the resultant sound quality of the instrument, this is a crucial area of research and study. Attempts to create man-made materials which reproduce the mechanical behavior of the woolen felt have fallen short.

There has also been a significant body of work attempting to create better mechanical models to describe the mechanical response of piano hammers in computational simulations. In addition, there have been efforts to create more detailed test devices that can better capture the mechanical response of piano hammers.

Of particular note is the work of Anatoli Stulov, et. al. in Estonia, whose dynamic evaluation of felt indicates strongly non-linear force-compression behavior, strong rate-dependency of the slope of the loading curve, and significant hysteresis between loading and unloading behaviors.

There are so many variations of engineering materials and uses of uncommon materials in specific applications, it would be unusual to find exact data on a specific material of interest. It is rare that a specific material has been characterized in exactly the conditions that are needed. It does seem unusual however, that such a common component of so many munition systems has apparently not been characterized for its shock behavior.

There are so many variations of engineering materials and uses of uncommon materials in specific applications, it would be unusual to find exact data on a specific material of interest. It is rare that a specific material has been characterized in exactly the conditions that are needed. It does seem unusual however, that such a common component of so many munition systems has apparently not been characterized for its shock behavior.

The mechanical characterization and resultant descriptive models created for felt used in piano hammers, while not at the specific strain rates of interest, can still be used as a reasonable surrogate until more appropriate characterization is done. Leveraging data and research from a completely disparate industry in this fashion is a very cost effective means of meeting immediate technical needs, and in some cases might completely alleviate the need for re-characterization.